Condition Monitoring – Don’t Have Stored Fuel Without It Part 1

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...

7 min read

Erik Bjornstad : Nov 9 2018

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the key elements of condition monitoring, why it’s important, and how you should be doing it. You can watch the recording of the webinar here, or you can read the transcript in this five-part series.

So, this brings us to our final slide here. We've covered an awful lot over the course of this. I think it ... I know it ran a little bit long. I tried not to let that happen but, there's a lot of detail in here. Hopefully besides, some useful tidbits about fuel microbiology and the important aspects of conditioning monitoring, I also hope that you've been able to come away with a sense that, this issue is a lot more complicated than it may seem. But beyond that, what they call 'microbial contamination monitoring and controlling it' is a never-ending process. It's not something that you do once, and you set it and forget it. It requires you to pay attention to what's going in your fuel, both if you want to prevent problems and if you want to fix problems properly when you find them.

Now, this is actually part one of a two-part webinar that, if I did them both together they'd be about two and a half hours long. And obviously, we don't have two and a half hours to spend. So, next month we're going to do the second part of this, which has to do with conditioned testing and remediation. Basically, how do you test these samples and then, what do you do based on the results that you find?

Now, my contact information, of course, is on the screen. I am going to get to the two questions that were poised. For those of you who may have had questions that you didn't want to ask or maybe, you think of something later. You have my email up on the screen. Many of the action steps that we've talked about in this webinar are ones that we typically, include in our best practices with the Bell Fuel and Tank Services, especially when it comes to microbial testing. We started this Bell FTS, Bell Fuel and Tank Services because we knew there was a lot of things to consider in this, and we wanted to make a complicated process as simple, and as cost effective for our customers as possible because we understand having done business with a lot of people like you over the years. We understand that there's a lot more to think about when taking care of mission-critical fuel and storage tanks.

And many times, it is helpful to have a partner that can come alongside you and guide you through the process. So, if that sounds like the situation that you're in, then I would definitely encourage you to touch base with me afterward and we'll see what we can do for you. So, the ... A few questions that were asked is ... Okay. So, Bill asked, some time ago he had said, "If we sump water from the tank, will the microbes be concentrated enough for a valid sample?"

Now, as I understand the question that you’re asking basically if you pull water from any sample. Now, this is assuming that that water is a ... Is actually representative of the microbial condition. There's going to be ... You asked, "Will the microbes be concentrated enough for a valid sample?" The answer to that is, most definitely yes. But, the ... I would have to ask the follow-up question to that which is, what are you thinking when you say 'valid sample'? I guess the most important definition of a valid sample, in this case, is, a sample that represents the actual condition that's in the tank. So, I'd say most likely, yes. But, if you're talking about a nuance of it that I'm not really getting at here Bill. Then, I'll actually follow-up with you by email afterward to make sure that I understand exactly what you're saying. Because I think I do but, not 100% sure.

Now, Sean asks, "Are you finding any deposits that aren't microbial related?" I assume what you mean is, if you took deposits from your tank, would you find deposits that aren't microbial related? Well, yeah. And again, yeah. I hate to say, 'it depends.' I say that a lot around here when some folks ask me certain questions. I say, "Well, it depends." When you say, "aren't microbial related." I'm not really sure how to answer that because I'm not sure what you're getting at by not being microbial related. I mean, microbial related that speaks to something like, biomass or biofilm. Stuff ... The biological matrix that's been formed by the microbes. And that they use as a home to help them grow and produce colonies and stuff like that.

Now, there are other kinds of deposits that are ... That form in a storage tank, right? If fuel has poor stability and starts to break apart, you'll get that sludge formation that's at the bottom of the tank. And sludge is typically a mix of a number of different kinds of things, right? Some of it ... If there's any microbial biomass, that will actually get mixed into that sludge sometimes. But the predominant parts of that will be non-microbial related. So, I don't know how well that answered your question. Again, touch base with me afterward because I get the sense that's a nuance of that, that I might not be getting at.

Folks at Davidson said, "Would you suggest sampling in the cooler months?" Absolutely. That is a very good question because what you have to realize is that the purpose of this sampling ... Well, sampling has a couple of purposes, but one of the purposes of the sampling is to see how your microbial levels change over time. And so, by definition, you have to sample during the cooler months. Now, some folks have said that, because microbes are, generally speaking, like to grow more when it's warm that they infer from that, that well they don't like to grow when it's cold. That is absolutely not the case. There are instances ... I mean, just go up to the Arctic and go to some of the pipelines and some of the drilling and things like that. There are plenty of problematic microbes, corrosion causing microbes, that grow just fine in cold weather.

Now, we don't have cold weather, really, down here in Florida. But, there's plenty of you all around the country that do. So definitely, you do want to sample in the cold weather because you need to see how the cold ... How the fingerprint of your system changes when the weather cools down.

Gary said, "Is fuel finishing something that will resolve issues with fuel water microbial issues?" Am I thinking you're asking about fuel polishing? I'm not really familiar with the term, fuel finishing, but given the context of what you're saying, I'm going to assume that you're talking about fuel polishing or some aspect related to fuel filtration. So, if we substitute filtration and we say, "Is fuel filtration something that will resolve issues with fuel, water, and microbial issues?" That's an excellent question there. Fuel, generally speaking when you ... When microbial contamination is found in a tank, and we'll talk about this a little more detailed in the next webinar. But, the bottom line there is that fuel filtration typically is, an important step to remediating the problem.

But it's one of what we say, three-pronged processes. You have to test properly, which is what we've been talking about all along. You also then have to do what we call, mechanical remediation. Now, mechanical remediation involves removing the free water, getting as much of that out as possible. But then, the other part of it is this filtration, this fuel finishing, what you're talking about. Because that's going to remove the biomass that's in the tank. And remember, we said you have to remove biomass because not only does it give a home for microbes to grow, it can cause corrosion in your tanks. So, the fuel finishing or the filtration removes that kind of stuff. And then, the last thing you do is, you chemically treat the fuel. You use a biocide to kill the microbes, which then have to be filtered out. Again, fuel finishing. And then there's other things that you can treat as well.

We'll talk about that more in depth in next month's webinar.

Then, Gary also ... "What about fuel separators on engines prior to going into the engine?" It depends what exactly you're asking with that. Are you asking that "Will a fuel separator on an engine resolve a fuel/water/microbe issue?" If that's the gist of what your question is then, what I would say is that you know, fuel separators as I understand them are designed to do things like, separate the coalesce and separate the water out. But if it's a microbial issue, it is absolutely not going to solve that because, the only thing that will solve a microbial issue is killing the microbes properly with a biocide, which means you need a chemical treatment. So generally speaking, fuel separators on the engines are not something that you're going to want to rely on in any subsequent fashion to solve fuel, water/microbe issues.

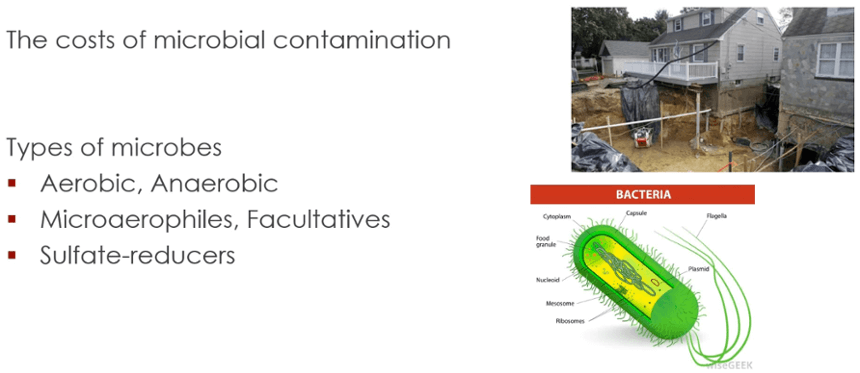

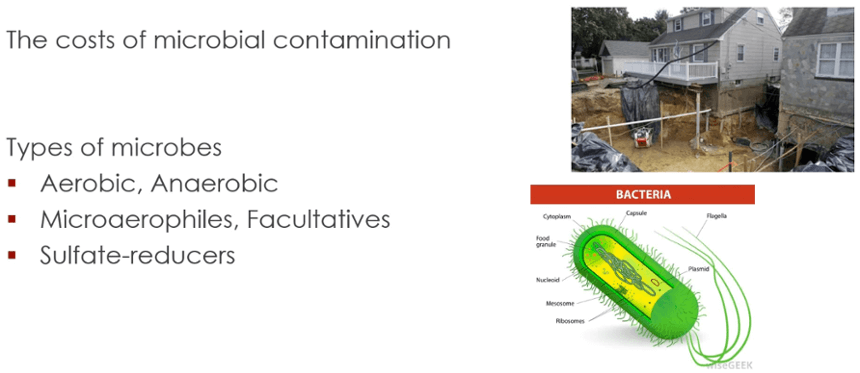

And then, the last question from our folks at Davidson, "Is algae a microbe?" Yes, algae is a microbe. You know we ... Algae is what people refer to ... Is the name people give my fuel microbes. They say, "I've got algae in my tank." Now, algae is a microbe; it's essentially a microscopic plant. But what we have to remember ... Remember at the very, very beginning I talked about you know; you've got bacteria ... Different kinds of microbes, bacteria, fungi, protozoans. I mentioned algae as the last one, and I said, "You're not going to find all of these in every place you go." And I said, "Specifically, it is very rare to find protozoans or algae in fuel systems. Because algae is a plant, it needs light to grow, and there's not a whole lot of light in." So when somebody tells us, "I've got algae in my tank." We know that they're not actually talking about algae. They're talking about some combination of bacteria and of fungi in their tank, and they're asking ... They're trying to find out what to do about that kind of stuff.

Alright, well that is the end of the questions. Thank you very much for those. If there's any I didn't get too or if any of these answers were incomplete for your purposes, touch base with me afterward I will be glad to help further. And, as I said earlier, you'll be getting an email with a link to the recording of this in case you want to pass it on to somebody else that you think might be able to use it. So, we've run a little long. But hopefully, it will have been in the service of a good cause. And, don't forget about the September webinar, you will be getting an email about that a little later so you can sign up and register for that.

So, I want to thank everybody for joining me, that was able to come. I am Erik Bjornstad with Bell Performance. Hope you all have a great rest of day and hopefully, we'll see you next time.

This is Condition Monitoring Part 3. You can read Part 1 here, Part 2 here, Part 3 here, and Part 4 here.

Watch the full presentation below:

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...