The fuel contaminants you need to watch out for

Crude oil comes out of the ground as a mixture of components formed from prehistoric plants and animals over eons of time. 142 refineries turn it...

2 min read

Bell Performance : Oct 1 2020

No matter if you use fuel in an ambulance or a backup generator, if the fuel quality is not up to par, then the vehicle or engine is not going to run properly (or at all) when it is needed most.

Poor fuel quality is really about what ends up in the fuel that does not burn as well as the fuel itself. When you hear about fuel oxidation, gums, varnishes and fuel sludge, they’re really talking about parts of the diesel fuel mixture that used to be soluble within the original fuel blend, but which have undergone chemical reactions over time. This creates sludge and other problems that ruin fuel. Fuel stability treatments keep these substances from forming, instead of keeping the fuel mix together so it burns as well as it is supposed to.

Of the common fuels in the marketplace – ethanol, diesel, bio diesel - these all have some common storage quality issues that can all be addressed with simple solutions. This post examines some of the common issues that are inherent to the preservation of these fuels, and how to ensure they’re ready for action. Understanding the root causes of the disruption of fuel quality in storage is the first step in setting up a fuel care protocol (or reexamining an existing one) that will ensure that you’re as prepared as possible when you need to respond to an emergency.

Diesel fuel is still the most common backup fuel stored in the United States. The diesel fuel in use today is not exactly like the diesel fuel that was in use 10, 15, or 20 or more years ago. The big difference between diesel fuels now and diesel fuels then is the level of sulfur allowed in the diesel fuel.

Biodiesel blends such as 2% or 5% biodiesel are more and more common in municipalities and organizations who face state, local and federal mandates to increase the volume of biofuels that they use in public vehicles. Higher levels of government are always happy to issue requirements dictating the behaviors of the entities below them.

Not only this, but biodiesel fuel users are also taking advantage of its natural lubricating properties, which can restore all of the lubricity properties of the diesel fuel that were lost when the sulfur was reduced by over 98%. A blend of as little as 2% biodiesel methyl ester into an in-spec diesel fuel base will restore all of the lost lubricity from the removal of the sulfur. This keeps these principalities from having to purchase additional lubricity additives from their fuel suppliers. So it is a win–win situation for these fuel usages. They get a high lubricating diesel fuel blend, and they get to claim a certain number of gallons of renewable biofuels used towards the mandate that they are seeping from further up the political food chain.

Ethanol blends are more sensitive to storage problems then diesel fuels. That may be because gasoline itself is more highly refined and more sensitive than diesel fuels. Ethanol blends attract water much more easily than diesel fuel blends. The ethanol molecule is a natural chemical attractor of water. Some take issue with the common parlayance of saying ethanol "pulls water in from the air". Technically it doesn't pull it in more than it readily absorbs the water that naturally comes in contact with the blend.

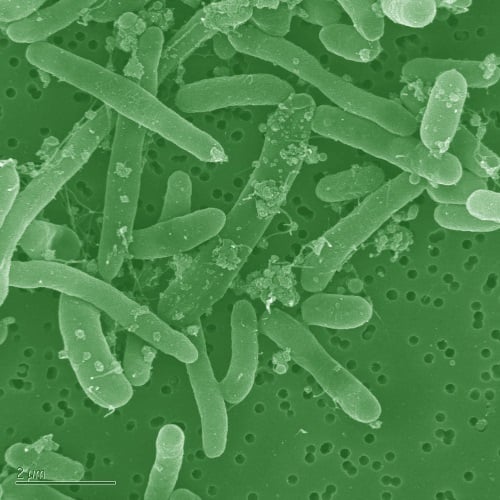

This water issue can be a big problem for stored ethanol fuel blends. This water accelerates oxidative and breakdown of ethanol fuels, contributes to the same type of microbial infestation problems in ethanol blends, and can initiate phase separation. Phase separation happens when an ethanol blend, such as a 5%, 10%, or 15% blend absorbs too much water from the atmosphere. When the amount of absorbed water exceeds the water tolerance of the fuel blend, the water absorbed will actually pull the ethanol out of solution with the gasoline. What ends up in the tank is a mixture of water and ethanol at the bottom with the remaining gasoline on top.

Use our Fuel Health Check tool to find out if your fuel is ready for emergencies.

Crude oil comes out of the ground as a mixture of components formed from prehistoric plants and animals over eons of time. 142 refineries turn it...

As we soon enter the 2025 hurricane season, many organizations are revisiting their emergency preparedness plans. One critical aspect often...

Sludge formation in stored fuels has always been a problem to reckon with. Today's ultra-low sulfur diesel fuels make it even more of a problem. And...