Condition Monitoring – Don’t Have Stored Fuel Without It Part 1

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...

Indeed, whether it’s monitoring for microbes or having fuel tested for physical or chemical specifications like cetane rating or flash point, proper sampling methods are critical to giving you the information you need. That’s why there are two entire ASTM process guides (D4057 and D7464) dedicated to telling you everything you need to know about how to draw good samples and how to handle them so your test results tell you what you need to know. And what you think they're supposed to be telling you.

That’s really the bottom line here. Fuel is sampled and the samples are tested because it’s assumed that the characteristics of those samples are similar enough to the characteristics of the entire fuel body that you can draw the same conclusions about one or the other. In other words, we have a psychological tendency to assume that what we're seeing in the fuel sample matches what it came out of.

In a different field, it’s the same with population sampling. Statisticians may want to know what the general populace of the country thinks about something (“who are you going to vote from as President”, “what do you think about x social issue”). But they can’t survey all 350 million people in the country. So they pick a representative sample of, say, 1100 people; a sample that (hopefully) reflects what the rest of the country really thinks.

In this case, the sample they get determines what they see. And the same is true with your stored fuel.

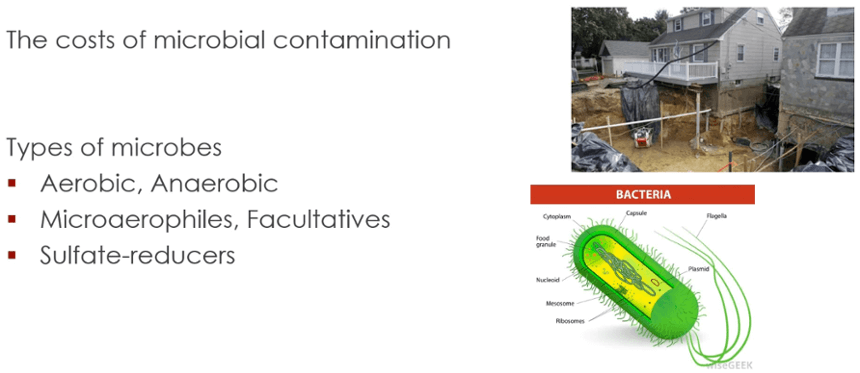

If you’re going sample your fuel to make a conclusion about the overall state of your stored fuel, make sure you’re following the right ASTM guidelines for sampling and handling. Especially if you’re doing an all-important microbial contamination test.

In fact, assessing microbial contamination might be the aspect that’s most sensitive to this principle. Fuel properties like flash point and cetane value tend to be evenly distributed through a fuel body. You’re not going to have much variance in this properties if you're testing samples that have been drawn from the top of the tank vs. the bottom. Water and sediment content might be one of the exceptions to this, but that's a story for another show.

The same is not true for microbial presence in storage tanks, because microbes are living bodies that congregate in certain areas of the tank. If you sample a tank but you miss the area where the microbes are, you’ll end up thinking there are no microbes in the tank. The sample you get determines what you see.

Or you take a good and proper sample, but you don’t put it on ice and you leave it in a hot truck for the afternoon. Now the microbial population has changed dramatically such that when you test it, maybe you’ve got 10x more microbes in your sample than you started with, a gigantic false population. The sample you get determines what you see.

As an aside, this is one of the problems with the older, first-generation "pen" ATP tests. Measuring ATP content in fuel is a valuable tool for assessing microbial presence. But the first tests they had used a pen apparatus to draw a really small sample (50 microliters) from the main sample. A "sub-sample" of the sample. The problem is that this portion was so small, it was easy to miss microbial ATP in the fuel sample itself, which led to problems with the accuracy of the results. Luckily, there are second-generation ATP by filtration technology that use larger sample sizes and give more accurate results for this important diagnostic practice.

You’re never going to know with 100% certainty how close your sample is to the real thing. That’s why statisticians calculate margins of errors. That’s why you have to stick with the recommended sampling methods for your stored fuel and have faith that standing on the shoulders of the fuels and scientific professionals having gone before you will get you where you need to be with respect to accurately seeing what’s going on with your own stored fuel.

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...

Back in the day, the storage life of both diesel and gas was measured in years, not months. That’s not the case anymore. Once you get past 6 months...

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...