Label Says 'Fights Algae' But Do You Need A Diesel Fuel Algaecide

When considering diesel fuel contamination by microbes, 'the devil is in the details'.

In the ever-evolving world of fuel management, new solutions frequently emerge promising to make life easier for fuel management professionals. It's a way of attempting to differentiate themselves in a crowded market. One such innovation, the solid biocide stick, has gained traction in the marketplace based on its apparent convenience and ease of use. However, as Erik Bjornstad explains in this deep dive into biocide technology, the reality is more complex than the bug stick marketing might suggest.

Understanding biocides and their role in fuel management is crucial. As Bjornstad emphasizes, "Applying biocides is the biggest key factor for resolving microbial contamination because in order to eliminate a microbial contamination problem, you have to kill the microbes." He makes the analogy of using the right tool for the job, in the same way as treating an infected wound – cleaning the wound isn't enough; you need an antibiotic to kill the infection.

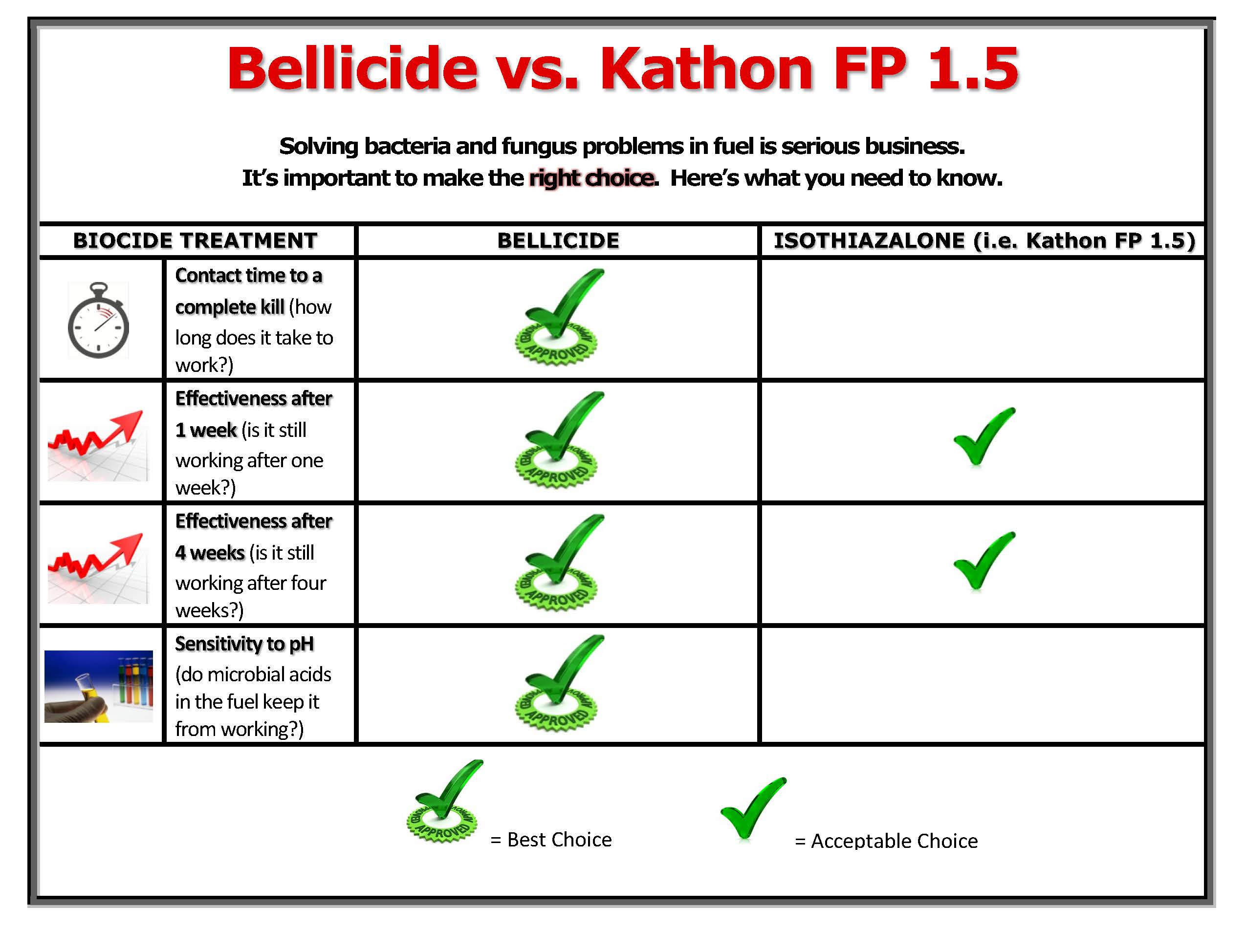

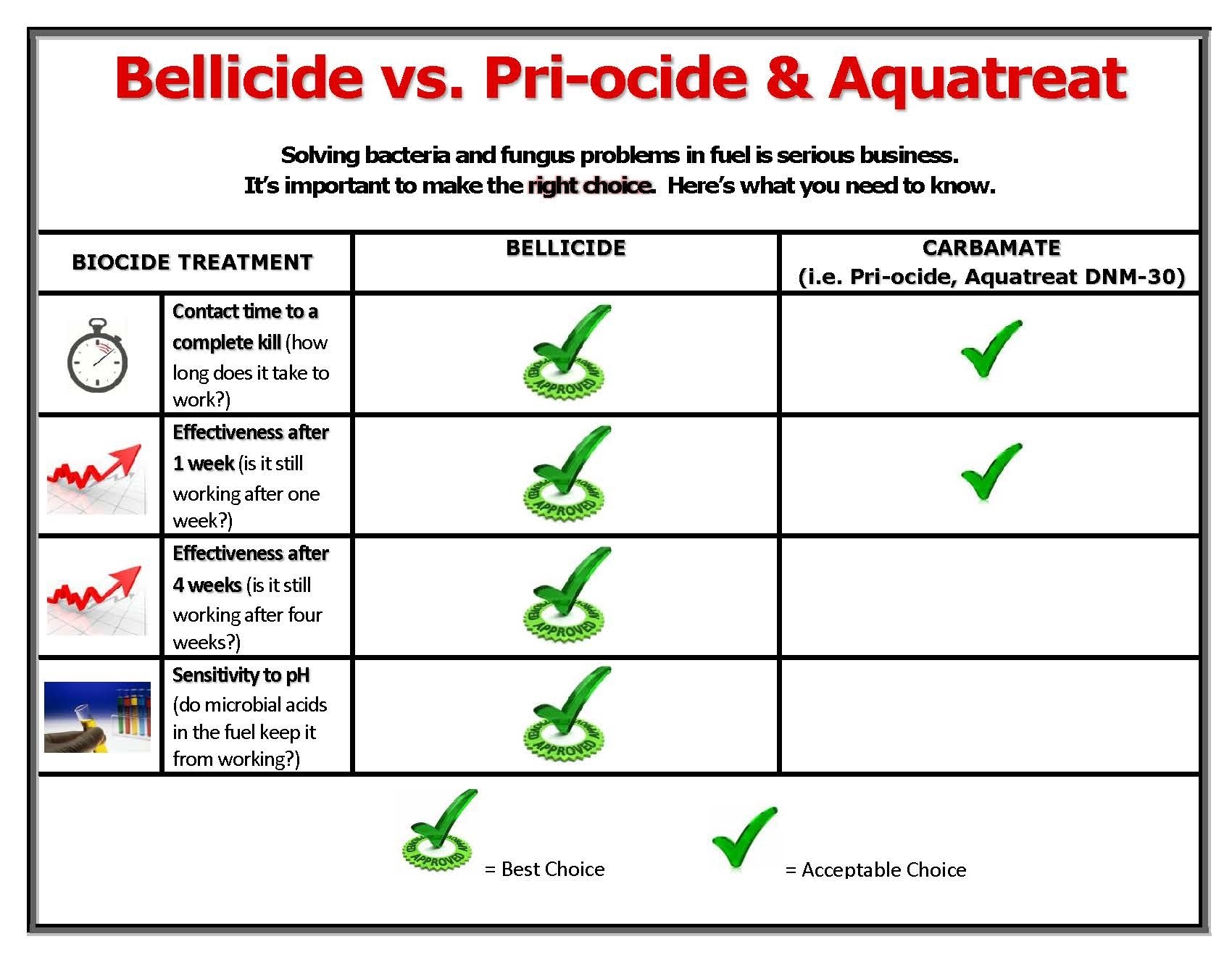

Currently, five well-known broad-spectrum biocides dominate the market: BioBor (diboranane chemistry), Bellicide (thiocyanate chemistry), Kathon (isothiazolinone chemistry), ClearKill (MBO chemistry), and Dow Fuel Saver (nitromorpholine chemistry). Each of these liquid biocides has been approved for use in fuels and fuel oils.

Now, enter the solid biocide stick – a new player using the bronopol chemistry.

The appeal of solid biocide sticks isn't hard to see. They promise a mess-free, easy-to-handle solution for treating microbial contamination in fuel storage systems. The marketing pitch often focuses on their convenience: no risk of spilling liquid biocide on a hot, sweaty summer day while working on top of a hot AST. Just drop in the stick and forget it – or so the pitch goes.

However, this simple argument masks several significant challenges. The first and most critical limitation involves regulatory approval. Solid biocide sticks containing bronopol cannot be legally used in on-road fuel applications. This isn't merely a paperwork issue – it's rooted in chemistry. Bronopol contains bromine, an element not normally found in distillate petroleum fuels, which fails to meet the EPA's "substantially chemically similar" requirement. Additionally, the calcium carbonate binder used to create the solid form also fails this requirement because calcium, too, isn't found in distillate fuels. According to the rules, you can't add anything to on-road fuel that contains any kind of element that is different from what's normally found in the fuel itself.

The technical limitations prove equally challenging. These sticks require specific conditions to function effectively. And this is a hurdle often overlooked when the positives are emphasized.

First, solid biocide sticks are water-soluble but not fuel-soluble, meaning they need a substantial water bottom layer to dissolve. While this works fine in massive industrial storage tanks that typically have significant water bottoms, it's problematic for smaller facilities like retail gas stations where water presence should be minimal (meaning these tanks don't usually have enough water in them for the sticks to be expected to fully dissolve).

Moreover, the sticks require consistent fuel flow – approximately five gallons per minute – to properly dissolve through what's called "erosion feeding." Without this amount of liquid flow rate, users often find partially dissolved sticks sitting in their tanks months or even years later, indicating insufficient treatment of the fuel.

Another more serious concern involves tank integrity. Industry reports have shown that partially dissolved bronopol sticks sitting on tank bottoms can damage the storage tank's integrity where they rest. This creates a potentially more expensive problem than the microbial contamination they were meant to address.

The chemistry of bronopol itself presents additional challenges, particularly in gasoline applications. When exposed to engine conditions, bronopol's bromine compounds break down into less volatile byproducts that can form damaging deposits on engine components like injectors. These deposits come from both brominated hydrocarbons and nitro compounds formed during combustion.

Perhaps most disappointing is the reality of the promised "micro-dosing" capability. Rather than providing a steady, consistent release of biocide, the treatment rate typically starts high and decreases over time until becoming negligible. This erratic dosing pattern undermines one of the primary selling points of the technology.

"Nothing is completely good, and nothing is completely bad," Bjornstad notes, but in this case, the limitations often outweigh the benefits for non-industrial applications. While solid biocide sticks have found success in specific industrial verticals like fuel production, pipelines, and bulk crude storage – environments that naturally mitigate many of their disadvantages – they remain problematic for typical fuel storage scenarios.

For fuel management professionals seeking effective solutions for microbial contamination, the message is clear: while solid biocide sticks may have their place in specific industrial applications, they're often not the best choice for typical fuel storage scenarios. Traditional liquid biocides, when properly applied, remain the more reliable option for most situations. Understanding these limitations helps managers make informed decisions about their fuel treatment programs, ensuring both regulatory compliance and effective microbial control.

When considering diesel fuel contamination by microbes, 'the devil is in the details'.

As fuel professionals across the nation check fuel storage tanks that may have been sitting for years, they're only now realizing the extent of fuel...

The changes to contemporary diesel and biodiesel fuels have created a huge need for fuel biocides to treat and protect those fuels in storage. Fuel...