Lithium vs. Calcium Sulfonate Grease – The Workhorses of the Industry

Selecting the best grease for an important job requires knowing some important things. All lubricant applications are the same and not all grease...

Grease compatibility is a key consideration when selecting a lubricating grease for an application. This is especially important in business and industrial situations where lubricant failure can have a particularly grievous price tag. Getting it right is important because of the cost of getting it wrong.

Grease compatibility comes into play when grease is being considered for use that may be different than the grease that was previously used. In these situations, the best practice is to clean out as much of the old grease as possible before introducing the new one. This can often be done by dispensing the new grease into the space, where it will displace the old product.

What’s the point of doing this? It may be more important than you think. If the two greases are incompatible, you run a much higher risk of grease lubricant failure. What makes greases compatible vs. incompatible? Which ones work well together and which ones don’t?

Greases are considered to be compatible if certain specifications of both greases are similar. Some specifications like copper strip corrosion (whether the grease will contribute to corrosion of metal surfaces) or oxidative stability (how well the grease stays together and resists reaction with prolonged exposure to air) are important but don’t affect their compatibility with other greases. But three specifications do play important roles as to whether two greases are compatible.

The rule of thumb here is that greases are considered to be compatible if the following things are true:

In other words, if you examine the Worked Penetration, the NLGI Grade under elevated temperature storage, and the dropping points, if the two greases to be mixed have specifications that are close to each other, they’re more likely to be compatible.

In situations where it is critical to make sure these are right, a customer will contact the grease manufacturer and arrange for bench testing of the specific greases in question to confirm these points.

Mixing incompatible greases can have dire consequences. They may react together and cause a separation of the base oil or oils from the thickeners of the two greases. When this happens, the base oil can no longer stay in place and you get a messy situation – oil oozing or running out of the area where it was applied. You can probably guess the potential consequences for the equipment that might follow from this happening.

Whether two different greases are compatible will depend mostly on the compatibility of the thickener used in the two products (although base oil compatibility can also be a consideration). Back in the old days, they used simple soaps and clay as the most common thickeners, and compatibility was easy to determine because you had a lot fewer combinations to consider. Soaps made from simple lithium and calcium were compatible with each other, but not compatible with clay.

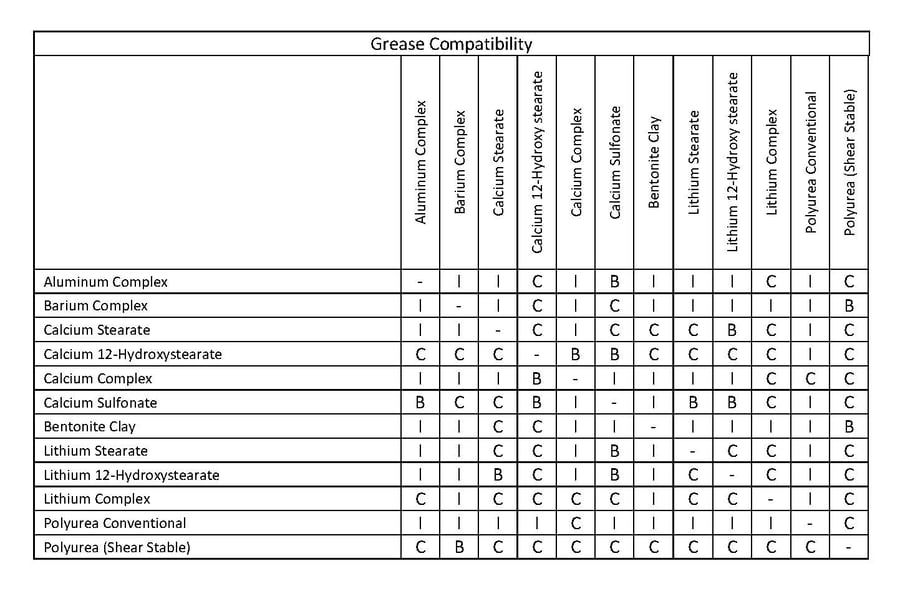

The situation is more complex today because there are so many more options to make high-performance advanced greases. Below is a compatibility chart that will give you a good idea of which kinds of greases play well with each other and which do not.

One thing that you will see on the chart is that polyurea greases seem to have the most compatibility problems. This may be because polyurea grease can be made from lots of different kinds of components, and react together to form something that falls under the umbrella of being called polyurea. So not all polyurea greases are the same and therefore there’s a lot more variance in their compatibility with other types of greases than you would first suspect.

B = Borderline

C = Compatible

I = Incompatible

That’s a lot of Bs, Cs, and Is on the chart, so here’s what stands out.

Selecting the best grease for an important job requires knowing some important things. All lubricant applications are the same and not all grease...

What would you expect from the world’s best wheel bearing grease? The answer to that question might differ from person to person, as no one grease...

In situations where high operating temperatures mesh with a need for effective grease lubrication, choosing the right grease is a critical decision...