Crude oil comes out of the ground as a mixture of components formed from prehistoric plants and animals over eons of time. 142 refineries turn it into the fuels that we use to get the job done. The world around us provides the bad actors that attack fuel when it’s stored and turn it into a problematic mess.

Wait, what? Okay, maybe not that dramatic. But fresh fuel doesn’t have high levels of contaminants that cause problems in engines and storage tanks. Those contaminants develop as the fuel is exposed to certain things over time. They attack fuel and initiate chemical reactions on the components of that fuel.

This is true whether you’re looking at regular diesel fuel, biodiesel, or even ethanol-blend gasoline. Although, gasoline tends to be used up pretty quickly, so in most cases it’s not kept around long enough to develop significant contamination. Ethanol gasoline's biggest issue is phase separation if it absorbs too much water. But we wouldn’t really classify that as a contaminant.

If you store fuel, you’re most likely to see the following kinds of things:

Asphaltenes – these are large, complex and heavy carbon molecules that normally exist in homogenous suspension with the fuel. So far, as good. Refined diesel fuel, at least the old high- and low-sulfur diesel, also contains natural dispersants that help keep these asphaltenes coexisting in harmony. But the refinery processing of ULSD ends up destroying a lot of these dispersants. So the asphaltenes become unstable and stratify and turn the diesel fuel dark a lot faster than in the past. These asphaltenes end up being a significant part of the dark sludge dropout you see in many fuel storage tanks.

Glycerides and water in biodiesel – we bring up biodiesel because most of the diesel fuel you’re likely to find at the pump has some amount of biodiesel already mixed into it. Even if it says it’s just regular old diesel fuel. As long as the biodiesel content is 5% of less, they don’t have to disclose it. Of course, there are also plenty of higher biodiesel blends out there, like B11 (11%), B20% and higher. Biodiesel naturally attracts water even more than ULSD does, which itself attracts water more than the old higher-sulfur diesel fuels did. But some biodiesel does make it into the marketplace without having been properly cleaned up after processing. This biodiesel fuel can have higher levels of different kind of glycerides and even excessive residual glycerin, a primary byproduct of biodiesel manufacturing reactions that’s supposed to be washed out of the fuel before it’s sold. These leftover contaminants can cause injector fouling and filter plugging, and they can attract excessive amounts of water into the biodiesel fuel. Unfortunately, if a given biodiesel fuel is contaminated with these, the producer isn’t exactly going to put that on the label, because that indicates a sloppy manufacturing process. In fact, biodiesel with excessive glycerin contamination can’t even legally be called “biodiesel”, when you get down to brass tacks.

The best recommendations to head off potential issues with contaminants like these?

Number one, use a fuel stabilizer. A good fuel stabilizer will contain ingredients that not only help neutralize the reactions to make asphaltenes unstable, but also help kept them from growing larger and turning the fuel dark and sludgy. Quality fuel stabilizers are relatively inexpensive but also essential preventive maintenance items for stored fuels of all kinds.

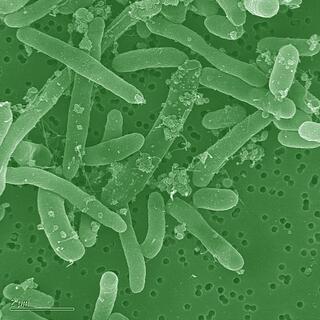

Number two, keep biocide on hand. Biocides are the only things that will kill microbial contamination in stored fuel. A practice as simple as adding a maintenance dosage of biocide to stored fuel every 2-3 months will go a long way to keeping any potential microbial contamination problems at bay.

You may be interested in these other articles on Fuel Storage:

- Fuel Contaminants: Rounding up the Usual Suspects

- "Wow" Facts on Contaminated Diesel Fuel. Be Prepared.

- 8 Signs of Diesel Fuel Contamination by Microbes, Fungus and Bacteria